SECONDARY FINISHES

We can offer secondary finishes on most of our metal mesh, such as decorative plating, powder coating, top coating and galvanize etc. as well as in a variety of colors and designs. Note that there are different maximum sizes of the surface-treated metal mesh depending on the type of surface treatment and metal mesh you want.

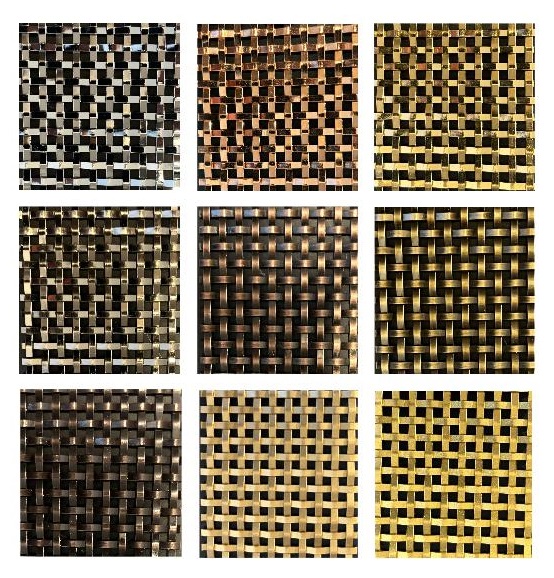

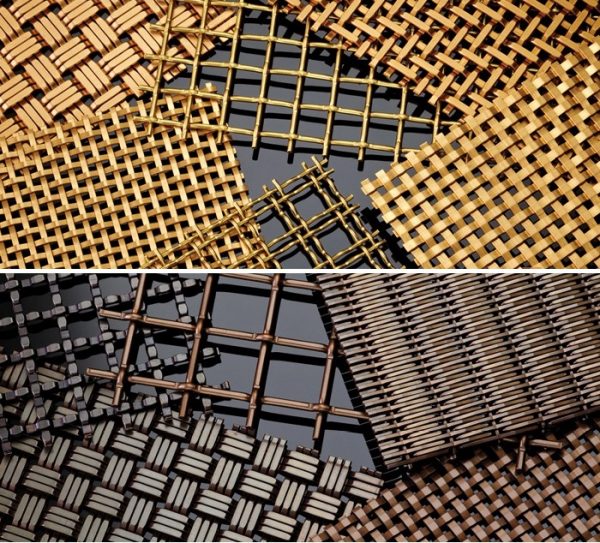

Decorative plating

Decorative plating is an electrodeposition process where a thin layer of brass, nickel, chrome, or copper is deposited on the wire mesh surface in a tank-dipped procedure. The color of plated metal mesh is generally correct, but since each metal finish is made by hand, the brightness can differ from one job to another. As the base alloy is made of ordinary steel, a plated surface is not suitable for outdoor use. Max dimensions plated metal mesh: approx. 1065mm x 2400mm. Unfortunately we cannot offer the finish “Dark Oxide Plated” any more.

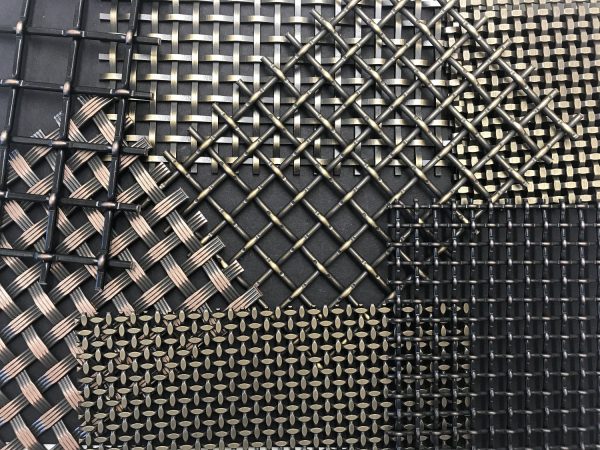

Antique plated finish

A decorative antique plated metal mesh have a base alloy of steel and a coating of other metal such as brass, nickel or copper. The antique plated finish process introduces a dark oxide layer over top of the bright plated alloy. Then, visual depth is created by physically relieving the high points of the wire mesh allowing the bright plated alloy to show through. A thin layer of lacquer is applied after plating to help preserve the finish from further tarnishing.

The color of plated metal mesh is generally correct, but since each metal finish is made by hand, the brightness can differ from one job to another. Since the base alloy is made of ordinary steel, a plated metal mesh is not suitable for outdoor use. Max dimensions plated metal mesh: approx. 1065mm x 2400mm

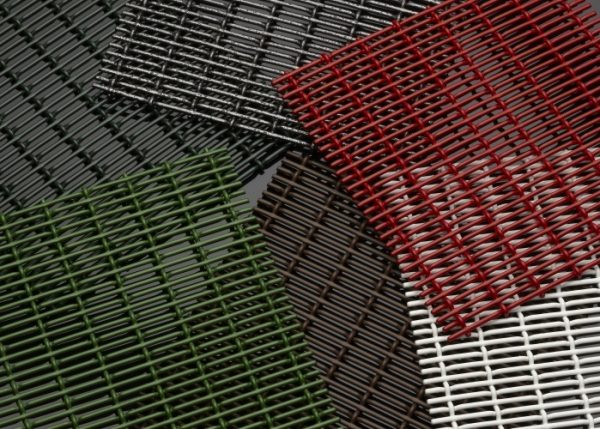

Powder coating

Powder coating is a cost effective way to add an unlimited range of colors to wire mesh. Powder coating uses an electrostatic charge to attract a fluidized powder evenly across all surfaces of the wire mesh. The electrostatic charge holds the pigmented powder until it passes through an oven where it melts and adheres permanently to the wire mesh. After curing, the wire mesh has a colorful and durable coating.

Powder coating alone provides adequate corrosion protection provided it does coat the product 100%. However, wire mesh is unique in that the round sections of wire are assembled in an over, under fashion. The intersection points (wire on wire) of the wire mesh will therefore not be coated by powder and the material will not be completely protected against corrosion. If conditions exist where corrosion is a concern (Interior or Exterior) then the wire mesh base material specified becomes very important. The most cost-effective solution would be to use pre-galvanized steel wire as the base alloy; the zinc provides good corrosion protection at the metal on metal intersections where powder does not reach.

Do not use solvents, sharp objects or abrasive cleaners on powder coated surfaces.

Our choice of powder coating on our products, is a standard powder coating that is used, powder-coated pure steel. Optional RAL color.

Galvanized metal mesh

Galvanized metal mesh is made of steel that has been coated with a very thin layer of zinc before the metal mesh is manufactured. It is only slightly more expensive than ordinary steel wire, but is much more corrosion resistant.

For powder coated metal mesh outdoors, galvanized steel should be used as the zinc layer protects the steel from rusting where the powder coating does not cover the metal to 100% in places where the steel wires cross each other.

The corrosion resistance with zinc is good, but the thicker the coating, the longer it takes for the zinc layer to corrode before the steel becomes unprotected. With galvanized steel, the wire coating is very thin, after which additional surface treatment is needed for the metal mesh to be suitable for long-term outdoor use. However, the performance increases sharply when used under a powder coated surface.

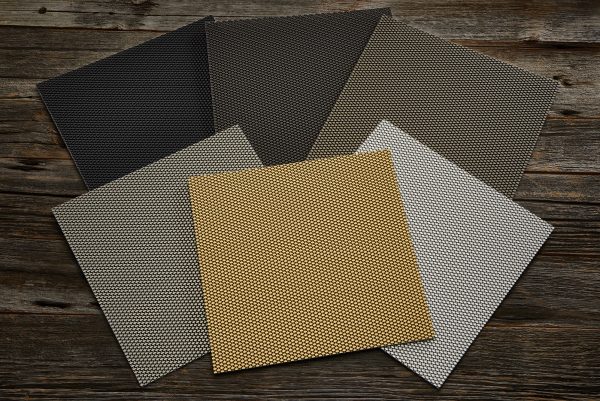

ANODISED METAL MESH

Metal mesh DSP.9 can now be offered in anodised aluminium. DSP.9 is a metal mesh made with tools that press the threads firmly before weaving, which creates a dense metal mesh without openness. Anodizing is an electrochemical surface treatment, where the colors merge with the material and preserve the metallic surface of aluminum. Aluminum is a light material compared to stainless steel or brass. Metal mesh DSP.9 in anodized aluminum is a good choice of material as weight is a decisive factor.

Anodized aluminum on the DSP.9 is now offered in six different colors with matte finishes: Champagne, Dark Bronze, Light Bronze, Black, Clear and Gold.

US10A and US10B-Finish

If you want metal mesh made of copper-based alloy to retain its lighter color or wish a little darker appearance, you can order metal mesh with a secondary finish US10A or US10B finish, which is possible on most of our rigid metal mesh for indoor use.

- The US10A finish physically removes the surface from the top layer of bronze, brass or copper and seals it with a clear top coat.

- The US10B finish creates a dark oxide layer on the surface of the metal mesh followed by a clear top coat.

US10A and US10B resist dirt only with the varnish application that is standard in the process. Without varnish, the metal mesh will continue to change depending on the environment. Metal mesh with surface layers US10A and US10B should be maintained and cleaned like a painted metal mesh.

Max sizes with secondary finish US10A & Us10B: approx. 1200mm x 2400mm. Contact us for more info.

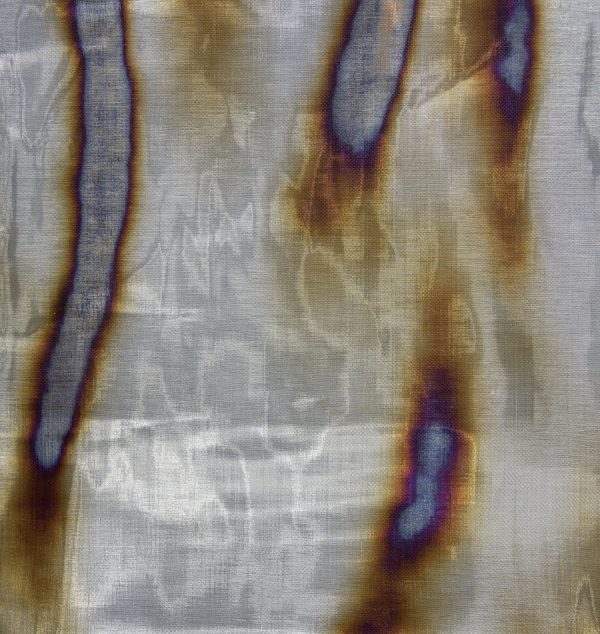

Burned metal mesh

Burned metal mesh be offered as a secondary finish on some of our malleable stainless steel metal meshes. Contact us for more information. The metal mesh has undergone a combustion process, which gives the metal mesh its unique flaming appearance with changing shades.

Metal mesh FIA.100 with burned effect is made of small diameter stainless steel metal wires to create a thin, transparent mesh.